About our Potent and

Non-Potent Downflow Booths

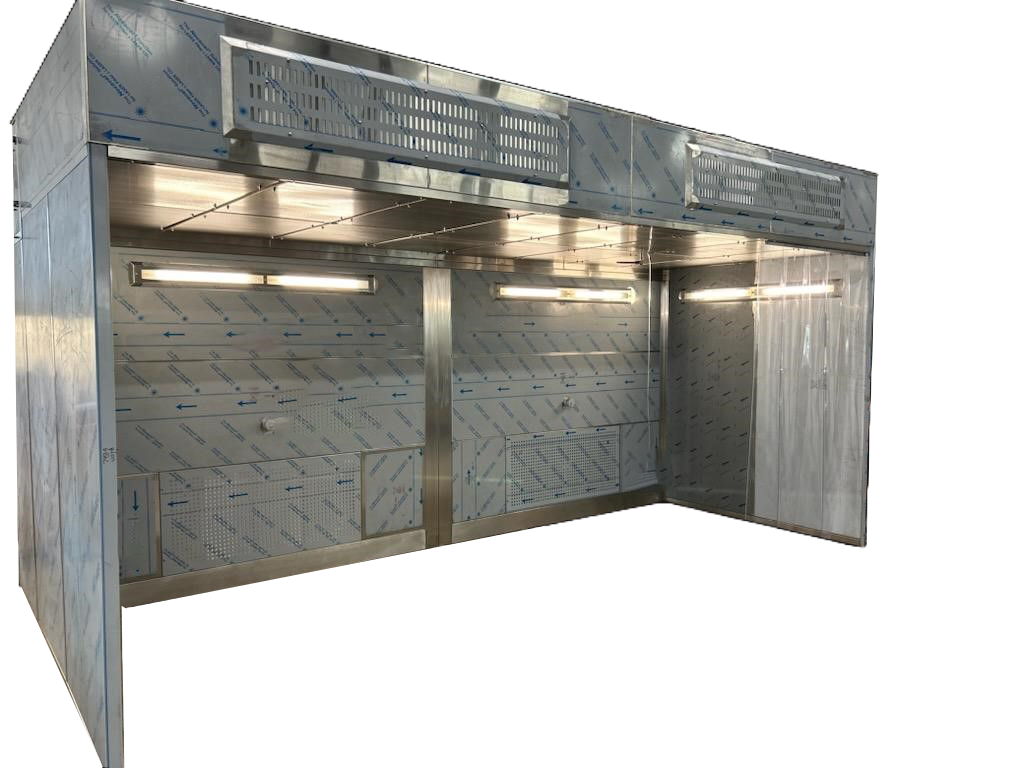

Laminar Flow Inc. is proud to manufacture a line of Downflow Booths for clean room solutions. Downflow Booths are customized to fit your specific needs and are supplied with either HEPA or ULPA terminal filters with return air thru the back wall plenum. Each system is configured per customer specifications. The patented construction of all LFI Downflow Booths ensures long-term low maintenance and reliable operation.

A completely self-contained system utilizing welded patent construction. Systems are fabricated entirely from heavy duty 14 and 16 ga 304/304L or 316L stainless steel with a #4 polished finish. Exterior welds are kept to a minimum, ground smooth, and polished. Continuously welded and formed patent filter grid ensures a completely self-contain leak free systems. Systems are shipped in sections with internal wiring completed in each section. Clean area walls are manufactured per customer specification, solid double pan stainless steel or clear panels in a tubing frame. Stainless steel overhead tubing at system entrance provides for curtain installation without penetrating filter plenum.

HEPA or ULPA filters are available. Gel Seal technology is utilized as a standard with all of our systems. This design allows for the gel trough to be around the filter and the knife edge integrally incorporated into the Filter Plenum. Perforated stainless steel grilles located downstream and flush to the interior protect the filter and provide even air distribution. Both serviced from within the clean area.

>> Provides up to ISO 5 99.9995 eff. to 0.3 microns

>> Supplemental movable screens available for lower OEL requirements

>> 2, 3 & 4 Stage Filtration Available

A completely self->

Product Options:

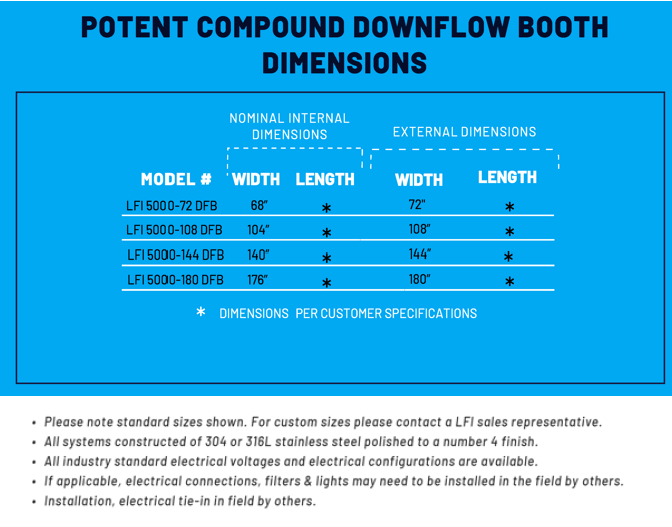

Series 5000 Downflow Booths

Designed to protect product and/or personnel with potent products with a classification of at least ISO 5

Perforated stainless steel grilles located downstream and flush to the interior protect the filter and provide even air distribution. Both serviced from within the clean area.

Downflow Booth Options:

Filter Information:

Series 1000 Downflow Booths

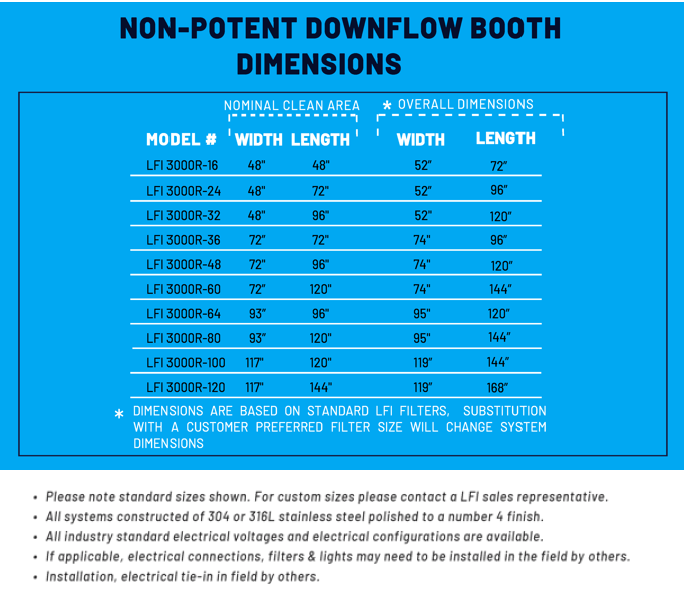

Designed to protect product and/or personnel with non-potent products with a classification of at least ISO 5 @ 0.3 micros.

Downflow Booth Options:

Electrical Features: