About Our Ceiling Systems

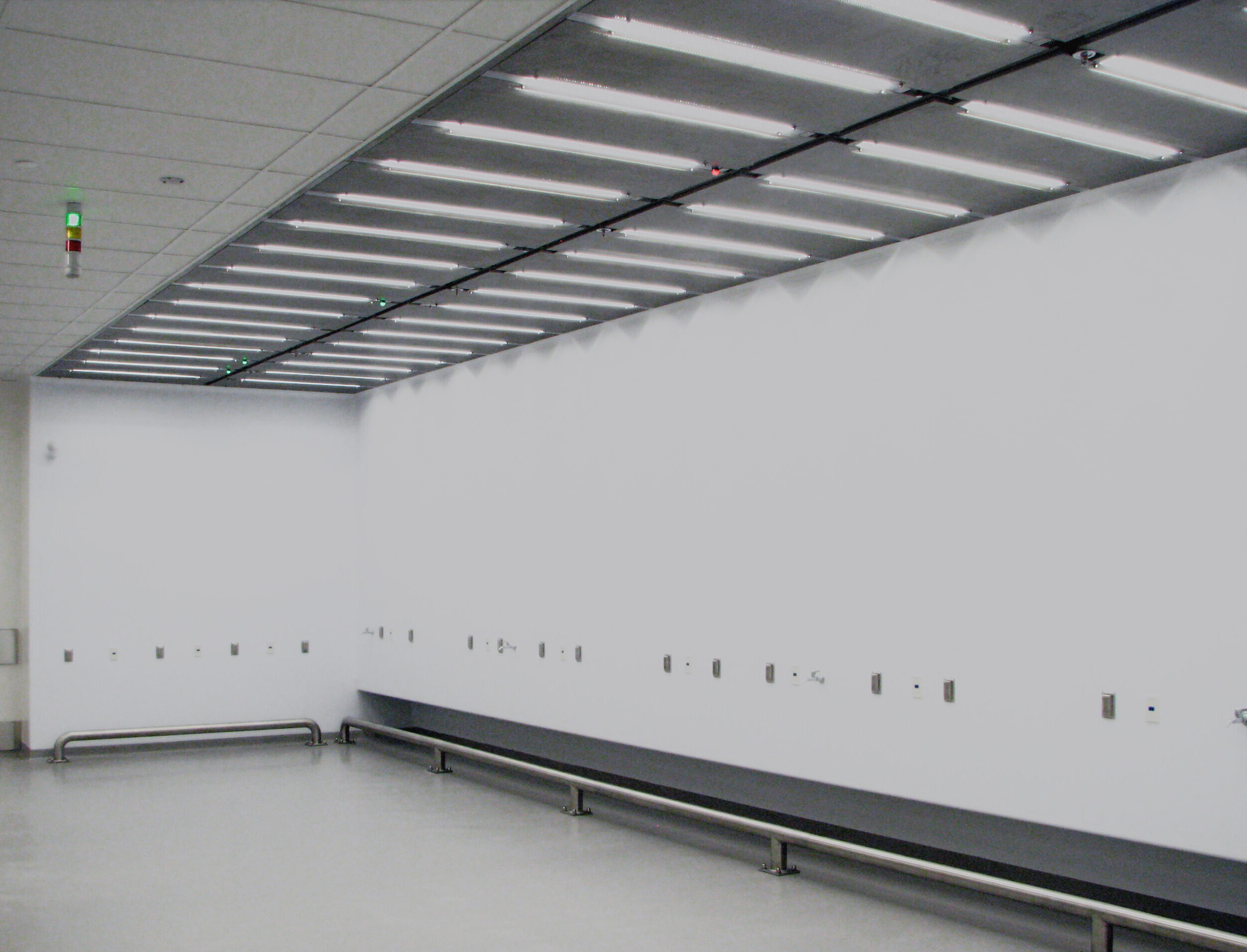

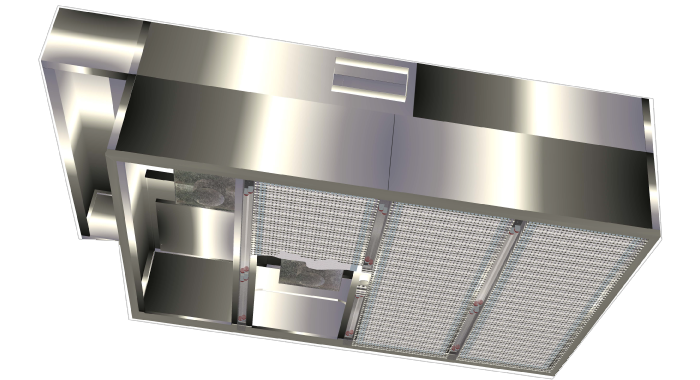

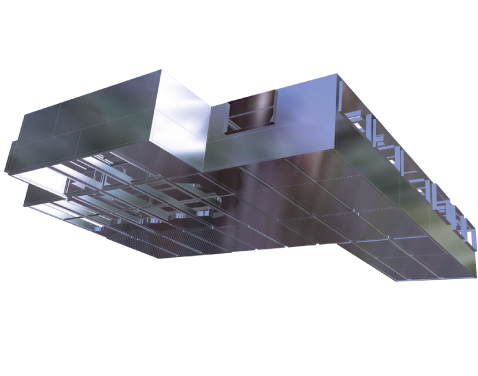

LFI Ceiling Modules are available in standard and custom sizes. It is a self-contained system available with many options including (but not limited to) custom size, electrical configuration, return walls, room configurations and specified filter sizes. The modular design allows for multiple unit sections to cover large areas and simplify shipment and installation. Modules are supplied with either HEPA or ULPA filters for ISO 5 or ISO 4 applications. Return/supply air for modules can be provided by duct connections for facility conditioned air or room side air return w/pre-filtration. Modules are configured according to customer specifications. Our patented construction ensures long-term, low-maintenance and reliable operation.

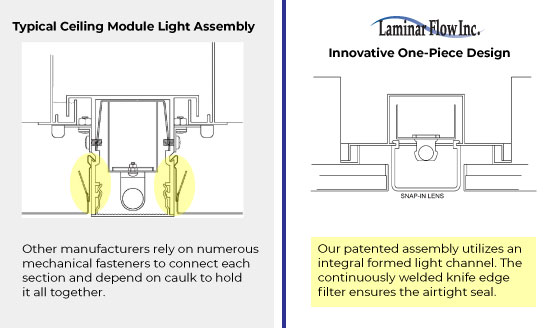

LFl’s ceiling module is a completely self-contained system utilizing patented welded construction. Systems are fabricated entirely from heavy-duty 14 and 16 ga 304/304L or 316L stainless steel with a #4 polished finish. Exterior welds are kept to a minimum and ground smooth and polished. Continuously welded and formed patented filter grid ensures a completely self-contained leak-free system. 1-piece formed light channels are recessed and continuously welded to the filter grid. Systems are shipped in sections with internal wiring complete in each section. Stainless steel perimeter tubing allows for curtain installation without penetrating the filter plenum.

HEPA or ULPA filters are available that provide up to ISO 4, 99.9995 % to .012 microns. Gel seal technology is utilized as a standard with all of our systems. Our patented knife edge is integrally incorporated into the module with continuously welded grid. This eliminates any chance for by-pass leaks. Perforated stainless steel grilles located downstream and flush to the filter protect the filter and provide even air distribution. Both can be serviced from within the clean area.

Options:

Systems are shipped in sections with internal wiring completed in each section. The patent-pending construction of all Laminar Flow Inc. Ceiling Systems ensures long-term, low-maintenance, and reliable operation.

Lighting Options:

All LFI lighting options feature stainless steel tubing that encompasses the light wiring and is sealed to the light channel. Our unique recessed light assembly features integral lighting between the filters, which enables tool-free maintenance. The flexibility of this system allows for the use of T-8, T-5, or LED lights. Teardrop light fixtures are also available with a T-8 or T-5 light tube.

Control Panel Options:

Series 3000 Ceiling System

Forward Curve Fan mounted on side of filter plenum for reduced overall height with access from side or below. Optional color touchscreen PLC/HMI.

Series 3500 Ceiling System

Backward Curve Fan mounted inside clean area for reduced overall height, access from top or below inside clean area. Filters must be removed to access from clean area.

Series 3638 Ceiling System

Forward or Backward Curve Fan mounted on top of filter plenum with access from top or below inside clean area. Filters must be removed to access fan from clean area. Completely self-contained, utilizing patented welding construction technique.

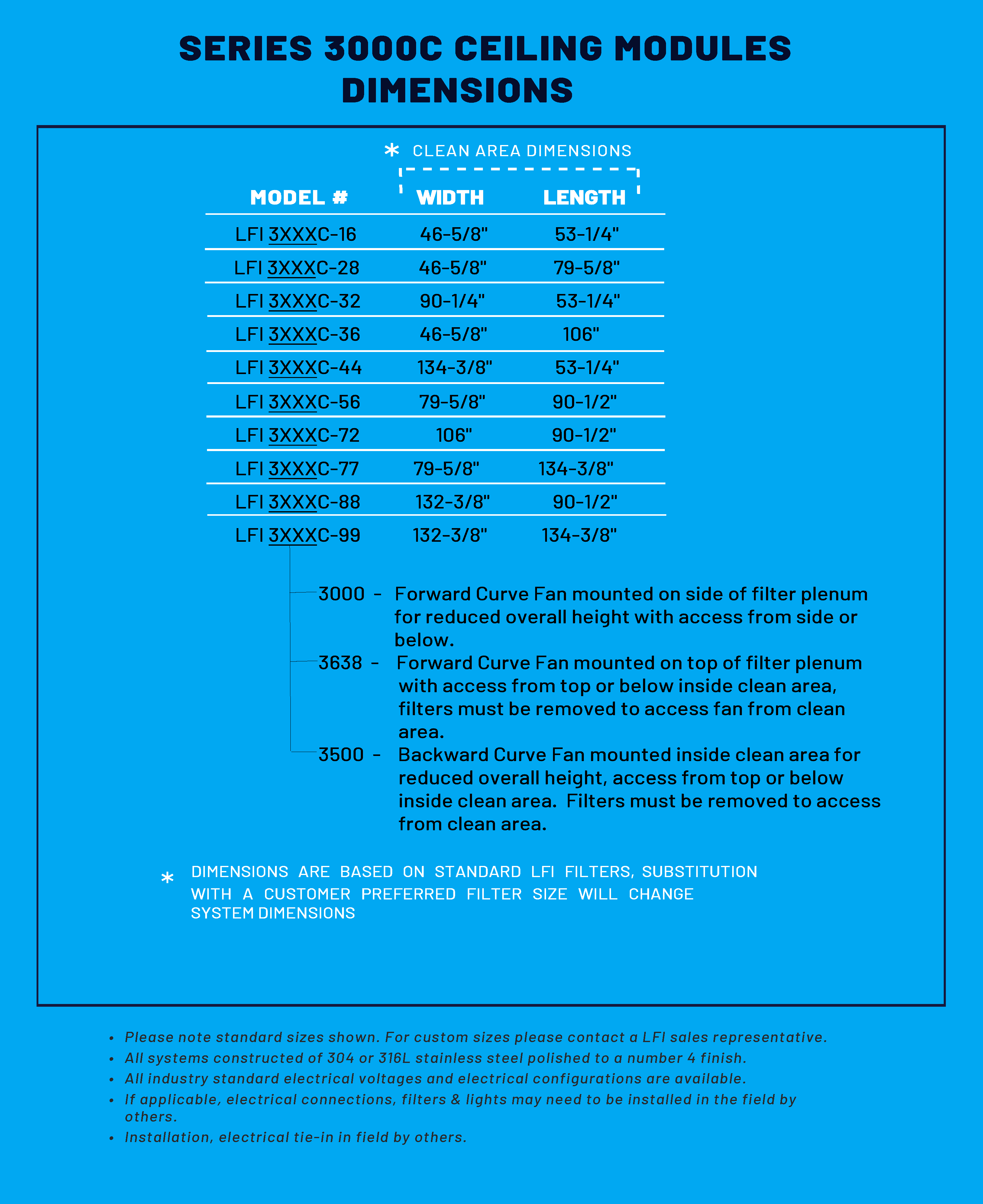

Size Chart